A pallet chain conveyor is a type of conveyor system specifically designed to transport heavy loads, such as pallets, within industrial settings. The pallet chain conveyor operates by utilizing a continuous loop of chains fitted with specially designed attachments that securely hold and transport the pallets along the conveyor line. These chains move along a predetermined path, guiding the pallets smoothly and consistently from one location to another.

Description

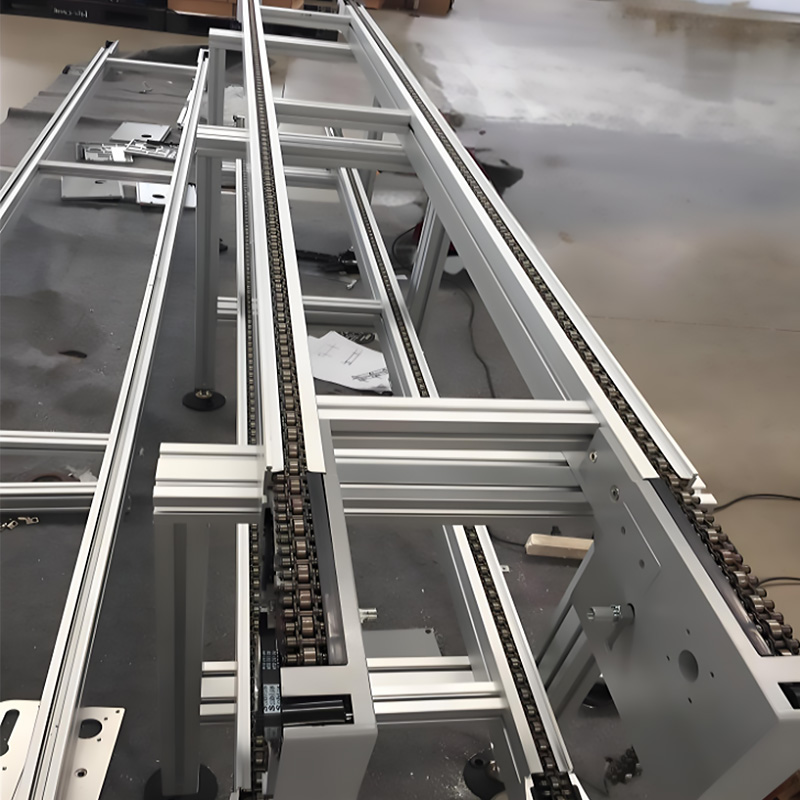

Pallet Chain Conveyor with 12BS Conveyor

The double-speed chain conveyor, also commonly known as the gravity conveying system, is mainly suitable for material transportation in assembly and processing production lines. Its conveying principle is to use the speed-increasing function of the double-speed chain to enable the tooling board supporting the goods to run quickly. And stop accurately at the corresponding operating position through the blocker.

Or complete the accumulation, transfer, transfer, and line transfer through the corresponding instructions. This kind of conveyor has the characteristics of large conveying capacity, fast speed, and high stability. Besides, it can achieve efficient material transportation and greatly improve the transportation efficiency of materials.

What is A Pallet Chain Conveyor?

A pallet chain conveyor is a type of conveyor system designed to handle and transport heavy loads, typically inmanufacturing, warehouse, and distribution center environments, Here are some key points about pallet chain conveyors:

Design and Structure

Chain Mechanism: These conveyors use parallel strands of roller chain to move pallets. The chains contact the palletdirectly, providing a stable and reliable method of conveyance

Modularity: Many pallet chain conveyors are modular, allowing for easy customization and maintenance. This modularityalso makes them suitable for various pallet sizes, including Euro and Industrial pallets.

Load Capacity: They can handle significant weights, often up to 2,000 kg, making them ideal for heavy-duty applications

Benefits

Efficiency: Pallet chain conveyors optimize handling operations, increasing throughput and flexibility in transportingheavy loads

Ergonomics: By automating the movement of heavy items, these conveyors reduce the need for manual lifting,improving workplace ergonomics and safety

Durability: Designed for heavy loads, they are robust and durable, ensuring long-term reliability

Application

Double-speed chain conveyors are widely used in many fields, including but not limited to:

1. Electronic and electrical industry: In the assembly and processing of electronic products, the double-speed chain conveyor can efficiently transport materials from one station to another, improving production efficiency.

2. Electromechanical industry: On the assembly line of electromechanical equipment, the double-speed chain conveyor can stably and quickly transport various parts to ensure the continuous operation of the production line.

3. Metallurgy, chemical industry, building materials and other industries: Double-speed chain conveyors can adapt to various working environments. It is including indoor, outdoor and harsh special environments, so we also use them widely in these industries.

In addition, double-speed chain conveyors can also cooperate with other automation equipment to form a complete automated production line. Through sensors and control systems, automatic transportation and processing of materials can be achieved. Thereby reducing human intervention and improving production efficiency and product quality.

In general, double-speed chain conveyors play an important role in production lines in many industries. Because they are in high efficiency, stability and flexibility.

What are the Double-speed Chain Conveying Equipment?

Double-speed chain conveying equipment is a device commonly for material conveying and transportation. It conveys materials from one place to another through the splints on the chain. Therefore, people use this device widely in industrial production, logistics warehousing and other fields.

1. Scraper chain conveyor: Scraper chain conveyor is a widely used double-speed chain conveying equipment, which is mainly composed of drive devices, chains, chutes and other components. During the material conveying process, the scraper on the chain will push the material to the target position. It is suitable for conveying various bulk materials, such as coal, cement, grain, etc.

2. Bucket elevator: Bucket elevator is a common vertical conveying equipment that uses buckets connected by chains to convey materials from low to high. Bucket elevator is suitable for conveying granular or powdered materials, such as ore, cement, etc.

Other Conveying Equipments

3. Chain roller conveyor: Chain roller conveyor is a double-speed chain conveying equipment that uses chain rollers as transmission devices. So people usually use it for conveying heavier materials, such as auto parts on automobile assembly lines, food on food processing lines, etc. Chain roller conveyor has the characteristics of simple structure and reliable operation.

4. Chain plate conveyor: Chain plate conveyor is a device that uses chain and plate carriers to transport materials. It is suitable for conveying high-temperature and corrosive materials. People usually use chain plate conveyors in metallurgy, chemical industry, cement and other industries.

5. Screw conveyor: Screw conveyor is a device that transports materials from one place to another through spiral blades. It is mainly composed of spiral shaft, blades, feed port and other components. Screw conveyor is suitable for conveying powdered or granular materials, such as grain, fertilizer, etc.