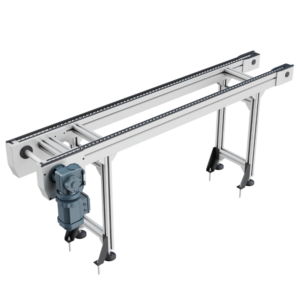

Gravity roller conveyor is an efficient and cost-effective solution for material handling. This conveyor uses the natural force of gravity to move items smoothly downhill, making it perfect for transporting boxes, packages, and other goods.

Versatile in its applications, the Gravity Roller Conveyor is perfect for assembly lines, shipping areas, and packaging operations. Additionally, we can customize it to fit your specific needs, with various lengths, widths, and roller sizes available. Optimize your workflow and enhance productivity with our Gravity Roller Conveyor.

Description

Toshine Low Cost Gravity Roller Conveyors Manufacturer

Gravity roller conveyors are commonly found in factories and industrial settings. They provide a straightforward, reliable, and budget-friendly way to transport parts, products, and packages. While roller conveyors may not be the perfect fit for every situation, many applications can greatly benefit from their use.

At Toshine, we specialize in custom conveyor solutions to enhance your production line at every step. Whether you need a gravity roller conveyor, a powered belt conveyor, or a tailored system with various integrated conveyors, we are ready to assist you.

How Gravity Roller Conveyors Work

Gravity conveyors operate by utilizing the natural force of gravity. The products rest on rollers that are positioned at a slight incline. This slope allows gravity to help move the items forward while reducing friction. As a result, this system consumes less energy, making it ideal for tasks that require significant labor.

When You use a Roller Conveyor in Your Production Line

While powered conveyors offer speed and flexibility, there are several scenarios where gravity conveyors excel. Many factories and warehouses use roller conveyors for assembly and packaging.

Here are some common reasons to consider incorporating a roller conveyor:

Your Process Requires Human Interaction: Roller conveyors have lower friction compared to belt conveyors. This feature makes them suitable for tasks where operators need to shift, rotate, or position products while they move. Since gravity conveyors operate at slower speeds, workers can easily interact with the items without interrupting the workflow.

You’re Moving Finished or Packaged Products: Gravity roller conveyors provide an effective solution for transporting finished items or packages. They allow for quick movement of products while minimizing the risk of damaging items. They have already completed the production process.

You Need a Cost-Effective Solution: One significant advantage of gravity conveyors is their cost savings. Compared to powered roller or belt conveyors, gravity conveyors are often more economical, especially for shorter runs. Additionally, with no moving parts or motors, maintenance costs are generally lower.

While gravity conveyors may not be suitable for every aspect of your process, identifying areas where we can utilize them, that can help reduce costs while maintaining high levels of efficiency and productivity.

Applications that Benefit from Gravity Roller Conveyors

Gravity roller conveyors can be effectively used in various production and packaging processes. They are particularly beneficial in the following situations:

Accumulation: When you need to collect products before moving them to the next stage, gravity roller conveyors are an excellent choice. They offer an efficient way to gather items for quality control and inspection.

Sortation: In sortation processes, products classification depends on specific criteria such as size, shape, or color. Gravity roller conveyors can assist in moving items to the appropriate areas, often with the help of a human operator or powered conveyor. That will make the sorting process less labor-intensive and more efficient.

Picking and Packing: Picking and packing tasks often require moving products in small increments. Gravity roller conveyors facilitate this movement easily. And their slower speed allows operators to manage the flow of products more effectively.

In summary, gravity roller conveyors are a versatile and cost-effective solution for various applications. They can help streamline operations while keeping costs down.

What is the difference between a powered conveyor and a gravity conveyor?

A motorized conveyor employs a motor to transport items along a designated route. Whereas a gravity conveyor depends entirely on gravitational force to move items down an incline, which means it doesn’t need an external power supply. In essence, motorized conveyors are capable of moving items in any direction, whereas gravity conveyors predominantly move items downward on a slope.

Key distinctions:

Power source: Motorized conveyors utilize an electric motor for item movement, whereas gravity conveyors rely exclusively on gravity.

Direction of movement: Motorized conveyors have the flexibility to move items in any direction, including uphill, whereas gravity conveyors are generally limited to moving items downhill on an incline.

Cost and maintenance: Gravity conveyors tend to be more cost-effective for installation and maintenance due to their lack of complex parts and absence of a motor.

Application: Motorized conveyors are optimal for applications requiring precise control over item movement and uphill transportation, whereas gravity conveyors are suitable for short distances where items can effortlessly roll down a slope.