Our pallet conveyor systems are designed to optimize operations in warehouses and distribution centers. Trust in our expertise to revolutionize your material handling processes and achieve exceptional results. Discover the transformative power of our state-of-the-art pallet conveyors today.

Description

The Evolution and Importance of Pallet Conveyors in Modern Warehousing

In the dynamic world of material handling and logistics, Toshine pallet conveyors have emerged as the backbone of modern warehousing. These robust systems are designed to transport pallets—flat structures that support goods in a stable fashion while being lifted by forklifts or pallet jacks—through various stages of processing and storage. This essay delves into the evolution, types, benefits, and future prospects of pallet conveyors in the industry.

Historical Context and Evolution

The concept of pallet conveyors dates back to the early 20th century when the need for efficient material handling solutions became evident with the rise of mass production. Initially, conveyors were simple, gravity-powered rollers or belts used to move products short distances.

However, the introduction of the wooden pallet during World War II revolutionized the system, leading to the development of specialized conveyors that could handle heavier loads and facilitate automated movement.

Types of Pallet Conveyors

In a word, there are several types of pallet conveyors, each tailored to specific needs and applications:

• Roller Conveyors: Utilize a series of rollers to move pallets by gravity or motor power.

• Chain Conveyors: Employ chains to drag or carry pallets along a guided path.

• Belt Conveyors: Use continuous belts to transport pallets, particularly suitable for fragile goods.

• Powered Roller Conveyors: Similar to roller conveyors but with powered rollers for controlled movement.

• Turntable Conveyors: Allow pallets to be rotated and directed towards different paths.

Benefits in Modern Warehousing

Pallet conveyors offer numerous benefits that make them indispensable in modern warehousing:

• Efficiency: They streamline the movement of goods, reducing manual handling and speeding up the process.

• Safety: By automating heavy lifting, they minimize the risk of workplace injuries.

• Scalability: We can expand or reconfigure conveyor systems to accommodate growing business needs.

• Integration: They can be integrated with other automated systems like robotic arms or automated storage and retrieval systems (AS/RS) for a cohesive workflow.

Challenges and Considerations

Despite their advantages, implementing pallet conveyors comes with challenges. The initial investment can be significant, and the complexity of installation requires careful planning. Moreover, maintenance is crucial to prevent downtime, which can be costly in terms of both repairs and lost productivity.

The Future of Pallet Conveyors

The future of pallet conveyors is closely tied to advancements in technology. With the rise of Industry 4.0, we can expect to see more intelligent conveyor systems equipped with sensors and IoT connectivity for real-time tracking and diagnostics. Automation will continue to advance, with conveyors becoming faster, more flexible, and capable of handling a wider variety of pallet sizes and weights.

Environmental Considerations and Sustainability

As industries become more environmentally conscious, the sustainability of pallet conveyors is also coming into focus. Manufacturers are increasingly looking at ways to reduce the carbon footprint of these systems. This includes using recycled materials for pallets and conveyor components, as well as incorporating energy-efficient motors and control systems that minimize electricity usage.

Economic Impact

Pallet conveyors also have a significant economic impact. They enable warehouses to operate with fewer staff, reducing labor costs. Additionally, the speed and reliability of conveyors can lead to faster order fulfillment, which can improve customer satisfaction and lead to increased sales.

Customization and Flexibility

Another important aspect of modern pallet conveyors is their customization and flexibility. We can design systems with modular components that allow for easy adjustments. This means that as a warehouse’s needs change, the conveyor system can change with it, without the need for a complete overhaul.

Conclusion

Pallet conveyors have come a long way since their inception, evolving into sophisticated systems that enhance efficiency, safety, and productivity in warehouses. As businesses continue to grow and seek out competitive advantages, the role of pallet conveyors will only become more pivotal. With ongoing technological improvements, the future of pallet conveyors looks bright, promising even greater levels of automation and integration in the warehousing ecosystem.

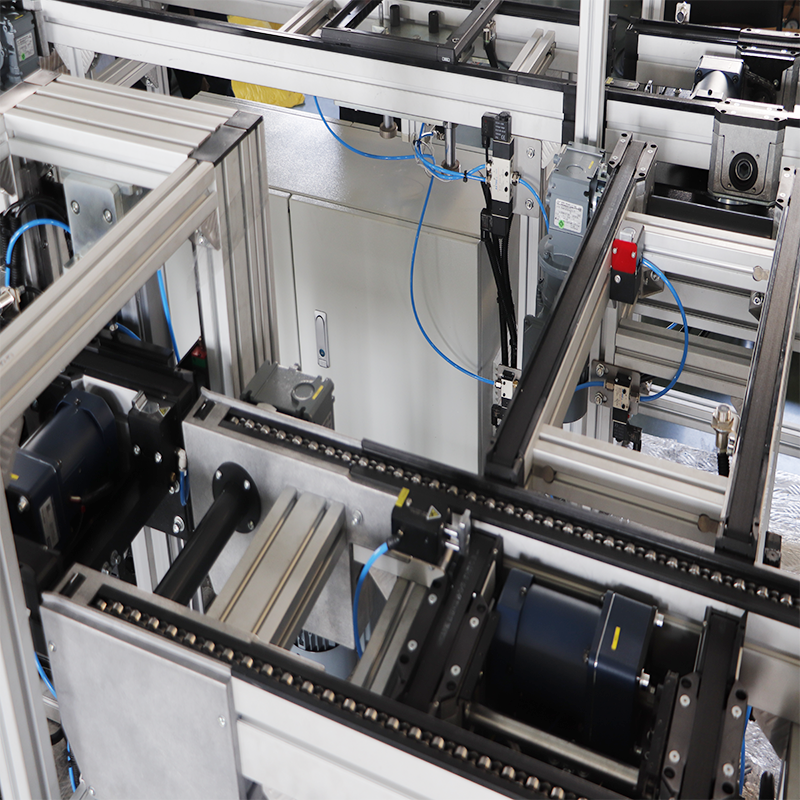

Our pallet conveyor system offers customization options for length and size, allowing for flexible deployment within your production line. With excellent sealing performance, it ensures minimal noise during operation, creating a conducive working environment.

Internally, the conveyor system comprises various components, including a conveyor belt, take-off roller, drive unit, brake unit, roller, redirecting device, tensioning device, loading and unloading device, and cleaning device. Each component works together seamlessly to optimize the conveyor’s performance.

The conveyor belts themselves are tailored to meet different usage scenarios. Most commonly, we offer plastic and rubber belts. Plastic conveyor belts exhibit excellent resistance against acids, alkalis, and aging, ensuring durability. On the other hand, rubber conveyor belts are suitable for larger slopes and can withstand fluctuations in temperature.

In summary, our customizable pallet conveyor system allows for flexible deployment within your production line. It operates quietly with superior sealing performance. Internally, it consists of a range of components that work harmoniously. While the choice between plastic and rubber conveyor belts ensures suitability for diverse scenarios. Experience the efficiency and versatility of our pallet conveyor system tailored to your unique needs.