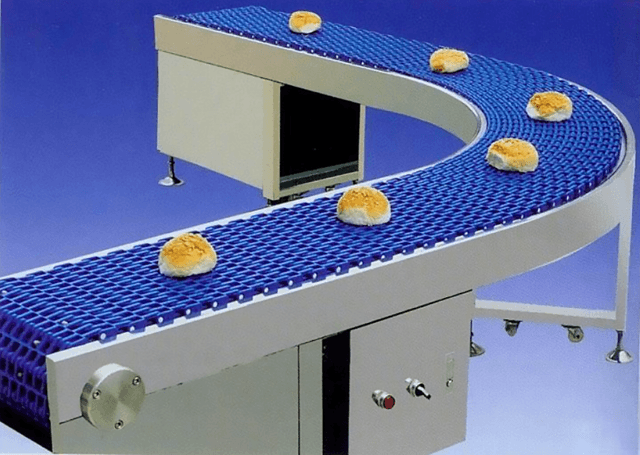

Mesh chain conveyors we offer is more than just a transportation device. It’s a comprehensive solution designed to enhance efficiency and streamline the handling of materials across a variety of industrial settings. Its reliability, combined with its significant adaptability, makes it an invaluable asset to any production line looking for an edge in operational productivity.

Описание

Приобретите сетчатый цепной конвейер оптом, чтобы повысить эффективность

The mesh chain conveyors operate by utilizing a network-style chain link to facilitate material movement from one location to another. Its operational mechanics rely on the propulsion of loaded materials via the rotation of the mesh chain for effective material conveyance.

We can construct this system typically from various components including a motor, a reducer, drive and conveying gears, along with the mesh chain itself. Upon activation, the motor transfers rotational power to the reducer, which in turn drives the gear system, instigating traction within the mesh chain, thus enabling the movement of materials.

Key Features of Mesh Chain Conveyors

Mesh chain conveyors exhibit several notable features:

- Durability and Trustworthiness: Owing to its simplistic yet sturdy design, the conveyor operates reliably and smoothly, minimizing the likelihood of breakdowns.

- Extended Conveyance Capability: This equipment can effectively transport materials across considerable distances, exceeding 100 meters in some instances.

- Versatility in Handling: Apt for a broad spectrum of materials, the mesh chain conveyor can handle items ranging from fine powders to bulky blocks.

- Efficient Use of Space: The conveyor’s compact design ensures it occupies minimal space and facilitates straightforward installation and commissioning.

- Тихая операция: The low operating speed of the mesh chain conveyor translates to a quiet, smooth running condition, fostering low noise levels and energy efficiency.

Applications of Mesh Chain Conveyors

The flexibility of mesh chain conveyors means they are employed in a variety of industries. They are including utility, химический, metallurgical, mining, as well as the food and grain sectors. Within the utilities sector, such conveyors are essential for transporting materials like ash and sand.

The chemical industry uses these conveyors to move substances like plastic powders and pellets, while the mining and metallurgical sectors depend on them for the movement of coal, ore, and similar materials.

Fundamentals and Care

The mesh chain conveyor system is a tailor-made production line we design for a set route to consistently move materials. Equipment for such systems may include either mesh belt conveyors or mesh chain conveyors, and the line accommodates various orientations – it can effectively function horizontally, at an angle, or vertically.

This capability allows for the creation of a spatial conveying pathway that is usually stationary. The conveyor line boasts an impressive capacity for handling large volumes over extended distances. Более того, it can concurrently execute multiple processing operations during transit, showcasing its extensive utility.

Mesh chain conveyors augment traditional belt conveyors. They are by rectifying some of their limitations such as susceptibility to tearing, прокалывание, and degradation. It accomplishes a safe, swift, and straightforward approach to maintenance and operation for users. The modular mesh belt and sprocket-driven mechanism ensure the conveyor belt is not prone to slithering aside or misalignment.

It also has the strength to withstand abrasions, воздействия, as well as resistance to oil, water, and other corrosive substances. The conveyor’s material versatility isn’t compromised, being able to operate efficiently between environmental temperatures ranging from -10° to 120°.

Multiple Mesh Chain

Multiple mesh chain configurations are possible. Including but not limited to flat top, flat grid, protruding rib. Or fan-shaped curved mesh chains, each with their distinctive characteristics and utilities across various industries. This includes sectors dealing with sensitive commodities like brewing, молочный, упаковка, части, meat processing, and the manufacture of containers. Более того, metal mesh chains are integral in processes that involve drying, heating, and cleaning of products.

Routine Maintenance Protocols

1. The optimal operating conditions for the mesh chain conveyor are a temperature range of -25° to 40° and a humidity level of less than 80%.

2. Ideally, the mesh chain conveyor should be positioned indoors, shielded from direct sunlight and away from direct water exposure.

3. The working environment should be free of corrosive or explosive gases and steam.

4. Only a qualified specialist should carry out maintenance on the mesh chain conveyor. This individual needs to possess a broad technical skill set and be well-acquainted with the conveyor’s capabilities.

5. Feeding materials onto the conveyor, we should evenly distribute to prevent misalignment or damaging the mesh belt due to uneven load.

6. Apart from authorized maintenance personnel, the conveyor should be inaccessible during operation; it’s important that no one makes contact with any of the moving components. Should an issue arise, we must stop the conveyor immediately. And only restart after resolving and assessing the issue.

7. Regular inspections should be conducted to check the tightness of all connecting bolts, with immediate action taken should any be found loose. People must not perform cleaning and repair activities while the conveyor is operational.

8. Beyond regular lubrication and the occasional replacement of parts, we can recommend a comprehensive overhaul every six months. This thorough maintenance should address any wear and tear or issues documented during use. It is including the replacement of any worn parts and lubricants.

Industrial Utilization of Mesh Chain Conveyors

In the realm of manufacturing, mesh chain conveyors are pivotal for material transport. And it is due to their consistent operation, capacity for moving materials across large distances, and adaptability. In mining applications, conveyors of this kind are essential for carrying coal or ore from mining sites to the surface.

The chemical sector employs them to transport both raw materials in granular form and processed products. Более того, these conveyors also find their place in the transportation of materials. They are within the food, напиток, and pharmaceutical industries, efficiently handling products like candies, biscuits, and beverage bottles.