Chain pallet conveyor, people widely use them in automated and semi-automated production lines such as food, confezione, automobili, home appliances, and electronics to achieve continuous or intermittent transportation of materials or workpieces. People also widely used in basic assembly lines to packaging lines, inspection lines, conveying lines, sorting lines, ecc., and are suitable for high-speed conveying occasions.

Inoltre, people can also use in military material assembly lines, logistics warehousing and conveying equipment, chemical industry conveyors, environmental protection industry conveyors, purification industry conveyors, wood industry conveyors, furniture industry production lines, tobacco assembly lines, eccetera.

Descrizione

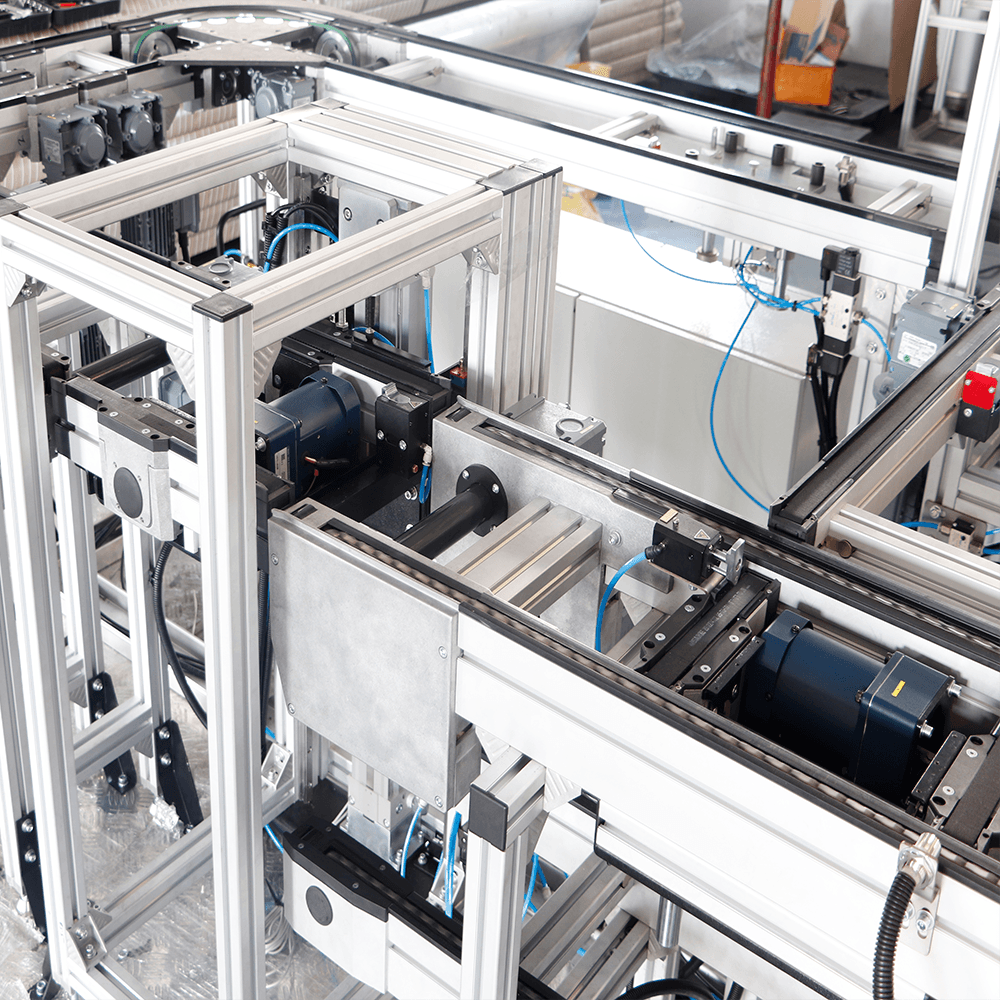

Sistema di trasportatore di pallet a catena economica in vendita

Chain pallet conveyor system is a common conveying equipment.

Basic Structure of Chain Pallet Conveyor

It is mainly including chain, sprocket, pallet, telaio, drive device and tensioning device.

- Catena: It is the key transmission component of the chain pallet conveyor. Generalmente, high-strength metal chain such as roller chain. The pitch and other parameters of the chain are selected according to the conveying capacity and speed requirements.

- Per esempio, in some occasions where it conveys light items, a chain with a smaller pitch may be selected. While for the conveying of heavy pallets and goods, a chain with a larger pitch and strong load-bearing capacity is in need.

- Sprocket: Meshes with the chain, and drives the sprocket to rotate through a drive device such as a motor, so that the chain moves. The tooth design and precision of the sprocket have a great influence on the transmission efficiency and stability of the chain.

- Pallet: People use it to place the conveyed items. The materials of the pallet are diverse, and the common ones are plastic pallets and metal pallets. Plastic pallets are light and corrosion-resistant, but the load-bearing capacity is relatively weak. Metal pallets (such as steel pallets) are strong and can carry heavier goods.

- But the cost may be high and they are prone to rust. People can customize the size of the pallet according to the size and shape of the actual conveyed items. And there are standard sizes and non-standard sizes.

Other Parts

- Frame: serves as a support structure for the whole conveyor, thus guaranteeing the stability of the equipment. People usually weld the frame with metal profiles (such as channel steel, angle steel or square steel). And its structural design should take into account factors. Such as the length, larghezza, height and load-bearing capacity of the conveyor.

- Drive device: Generally includes components such as motors and reducers. The motor provides power, and the reducer is to adjust the output speed and torque. So that we can convey the chain at the appropriate speed and force.

- Per esempio, in some automated production lines that require precise control of the conveying speed, a high-precision variable frequency motor and reducer combination will be selected to achieve conveying requirements at different speeds.

- Tensioning device: Used to adjust the tension of the chain. Since the chain may elongate during long-term operation, the tensioning device can ensure that the chain always maintains the appropriate tension. That will avoid chain failures such as tooth skipping and chain derailment. Common tensioning devices include screw tensioning devices and heavy hammer tensioning devices.

- The screw tensioning device adjusts the position of the tensioning wheel by rotating the screw, thereby changing the tension of the chain. The heavy hammer tensioning device uses the gravity of the heavy hammer to automatically adjust the tension of the chain.

Working Principle of Chain Pallet Conveyor

The chain pallet conveyors drive the sprocket to rotate through the drive device, and the sprocket drives the chain to circulate. The chain will drive the goods that we place on the pallet and move along the established conveying route. Its conveying route can be linear, or it can achieve complex conveying paths such as turning through special sprocket arrangements and track designs.

Per esempio, in a logistics warehouse, the chain pallet conveyor can transport goods. It is from the storage area of the warehouse along a straight line to the sorting area. And then divert the goods to different sorting channels through the curve conveyor.

Features and Application Scenarios

Features

- Strong carrying capacity: It can transport heavier pallets and goods. And it is suitable for the transportation of large and heavy items. Per esempio, in automobile manufacturing plants, people can use chain pallet conveyors to transport heavy parts such as automobile engines.

- Stable conveying speed: Through a reasonable drive and speed regulation system, that can maintain a relatively stable conveying speed. That is conducive to synchronous conveying on an automated production line.

- High positioning accuracy: It can transport pallets and goods to designated locations more accurately. And that is convenient for subsequent processing, assembly or storage operations.

- Adapt to a variety of working environments: Due to its relatively strong structure, it can work under different environmental conditions. Such as temperature, humidity and dust.

Application scenarios

- Logistics industry: In logistics warehouses and distribution centers, people use it for the warehousing, storage, sorting and outbound transportation of goods. Per esempio, pallets filled with goods are transported from the loading and unloading area to the shelf storage area. Or we will transport pallets that need ship from the storage area to the shipping area.

- Manufacturing industry: On the production line of the factory, people use it for the transportation of raw materials, semi-finished products and finished products. Per esempio, in an electronic product manufacturing factory, semi-finished products. Such as circuit boards are transported from one processing station to the next processing station. In a machinery manufacturing factory, parts are transported for assembly, eccetera.

- Food and beverage industry: Transport packaged food or beverage products. Per esempio, that will transport boxes of beverages from the production packaging line to the warehouse for storage. Or it will transport processed food pallets to the cold chain warehouse for refrigeration in a food processing plant.